Union Autoparts Manufacturing Co., Ltd. (UAM) had been founded since 1982, as the Manufacturer and Distributor of Spokes & Nipples and Steel Wheel Rim for Motorcycle Industry and also as the Motorcycle Wheel Assembler for Motorcycle Assembly Plant both domestic and overseas plant. Our Service expanded to include Surface Plating for Automotive Parts& all kind of industries, Piping & Pipe products , and Exhaust Pipe for automotive Industry as well.

We strongly emphasize on Product Quality as the most important goal, together with Continuous Development of Management Systems and Advance Technology, with Strong Quality Systems Control from Manufacturing to Delivery Quality Product and Services to Customers On-time. Customer Satisfactions and Acceptance from both Domestic and Overseas customers are also our key goals to be achieved

- Outline

- History

- Certification

- Quality Policy

- Quality Control Equipment

- Lab & Process Control

- Environmental Policy

- Awards

- Shareholder Information

Union Autoparts Manufacturing Co., Ltd.

| Head Office | Factory 1 | 102 Moo 6 Poochaosamingprai Rd., Samrongtai, Phrapradaeng, Samuthprakarn 10130, Thailand. TEL : (02) 183-3872 (Auto 12 lines) FAX : (02) 183-3884-5 |

| Factory 2 | 51/6 Moo 15 Poochaosamingprai Rd., Bangyapraek, Phrapradaeng, Samuthprakarn 10130, Thailand TEL : (02) 722-5168-73 FAX : (02) 394-1285 | |

| Factory 3 | Siam Eastern Industrial Park 60/75 Moo 3 Mabyangporn, Pluakdaeng, Rayong 21140 Thailand. TEL : (038) 891-999, (038) 885-001-8 FAX : (038) 891-697 | |

| [email protected] | ||

| Website | www.uam.co.th | |

| Establishment | August 03, 1982 | |

| Share Holders | Okaya & co., Ltd., Japan 98% | |

| Capital | Baht 350 Million paid up | |

| Turnover | Baht 2,300 Million | |

| Main Product | Motorcycle Parts | Steel Wheel Rims (UNION CYCLE, UAM) Brand Spokes & Nipples (UNION, UAM) Brand |

| Plating Services | Zinc plating/Zinc-nickel plating/Ni-Cr plating/Electroless Ni for Automotive parts, Electronic parts and Other. | |

| Wheel Assembly | Wheel of Motorcycle and Golf cart. | |

| Piping System | Piping products (fuel, oil, air, water...etc) & Pipe Products (head rest pipe...etc) for automotive. | |

| Precision Pipe | Stainless Steel EFW Pipe for Automotive Exhaust Pipe | |

| Public Awards | ISO/TS 16949, ISO 14001 and Thailand Trust Mark | |

| Employees | 950 Persons |

Union Autoparts Manufacturing Co., Ltd.

| 1982 | Joint venture between Thai and japan by Siam Steel International Co.,Ltd, Thailand : 51% Okaya & Company Co.,Ltd., Japan : 49 %, with the initial capital 15 million Baht.(3/8/1982) To produce : 1. Motorcycle Rim 2. Spoke & Nipple 3. Service Plating |

| 1983 | To receive the promotion from the B.O.I. |

| 1988 | To increase the capital to be 35 million Baht. |

| 1992 | To increase the capital to be 63 million Baht. |

| 1994 | Joint venture between Goshigiken Co.,Ltd. and HPD Co.,Ltd in name of Siam Goshi Mfg. with the initial capital 60 million Baht. To extend branch 1 (Factory 2) with the value 104 million Baht is located Siam Steel Group, to produce Spoke & Nipple. |

| 1995 | To increase the capital to be 80 million Baht. |

| 1996 | To increase the capital t be 100 million Baht. |

| 1997 | Siam Goshi Manufacturing Co.,Ltd. increase the capital to be 180 million Baht , UAM's shares are changed from 36% to 18% |

| 1999 | Siam Steel International PLC. sell stock 4,898,947 shares to the Okaya & Co.Ltd. So UAM have Okaya & Co.,Ltd.'s shareholders 98%. To receive the certification of ISO 9001 : 1994 Standard by BVQI. |

| 2000 | To receive the certification of ISO14001 : 1996 Standard by RWTUV. |

| 2001 | To expand the product "Service Plating for Microporous"with the value 100 million Baht at Factory 2 |

| 2002 | To receive the certification of QS 9000 Standard by RWTUV. To increase the capital to be 130 million Baht. To receive the certification of ISO 9001 : 2000 by RWTUV. |

| 2003 | To increase the capital to be 160 million Baht. To receive the promotion from the B.O.I. at the Rayong. |

| 2004 | To increase the capital to be 200 million Baht. To receive the certification of JIS Standard (D 4215 -1995) |

| 2005 | To increase the capital to be 250 million Baht. To receive the certification of ISO/TS16949 : 2002 by TUV NORD. To expand in Philippines " UAM Philippines INC" with the initial capital 135 million Peso. |

| 2006 | To increase the capital to be 300 million Baht. To expand branch 2 phase 1 (Factory 3) "Spoke & Nipple" with the value 115 million Baht at Siam Eastern Industrial Park Rayong. To receive the certification of ISO/TS16949 : 2002 by TUV NORD (Spoke & Nipple - Factory 3) |

| 2007 | UAM Philippines INC to increase the capital to be 155 million Peso. |

| 2008 | To expand branch 2 phase 2 (Factory 3) " Service Plating Bumper" with the value 300 million Baht at theSiam Eastern Industrial Park Rayong. |

| 2009 | Re-certification for ISO/TS16949 by Bureau Veritas Certification (Factory 1, 3) To receive the certification of ISO/TS16949 : 2002 by Bureau Veritas Certification (Bumper - Factory 3) To expand branch 1 (Factory 2) " Piping System"with the value 150 million Baht at Siam Steel Group. |

| 2011 | To expand investment 25 millon Bath "EP-10 Ni-Cr Plating" at Factory 3. |

| 2012 | To increase the capital to be 350 million Baht. To receive the certification of ISO/TS16949 : 2002 by Bureau Veritas Certification (Piping System - Factory 2) To receive the certification of ISO14001 : 2004 by AJA (Factory 2). |

| 2013 | To expand branch 2 phase 3 (Factory 3) " Precision Pipe and Electroplated Coating of Zinc (EP11)" with the value 350 million Baht at the Siam Eastern Industrial Park Rayong. To expand investment 1 millon Bath "Electroless Ni" at Factory 3. |

| 2016 | To expand Wheel Assembly Line for scope of ISO/TS16949 Certification. |

| 2017 | Modification from ISO/TS16949 system to IATF 16949 system. |

| 2019 | Change Certification Body (CB) from AJA to Socotec. |

International-Quality Products

A Caring Hand for the Environment

Quality Control

| Years | Qualifications | Institutes |

| 1999 | ISO9002 : 1994 |  |

| 2002 | ISO9001 : 2000 |  |

| QS9000 |  | |

| 2004 | JIS STANDARD ( D 4215 : 1995 ) |  |

| 2005 | ISO/TS16949 : 2002 |  |

| 2008 | ISO/TS16949 : Second edition |  |

| 2011 | ISO/TS16949 : Third edition | |

| 2014 | ISO/TS16949 : 2009 | |

| 2018 - Now | IATF 16949 - First Edition |  |

We establish internal affair policies, to which we adhere to accordingly, purpose to continue improving our organization and maintain customer’s highest satisfaction.

Union Autoparts Manufacturing Co.,Ltd. quality control policies

- Customer’s satisfaction on service and overall expectation are to be evaluated appropriately on regular basis.

- Take account of supplier regularity.

- Encourage possibilities to improve the manufacturing, either by keeping up with technology insight information of ways to lessen waste or promoting manufacturing capacity and product quality etc.

- Follow up customer’s complaints and earnestly attain the best possible solutions.

- Delivery MUST be handled with 100% of accuracy

- Arrange necessarily educational programmed for staff at all levels.

- Support safety and environmentally related activities.

Client’s satisfaction is the most important to run our company. The Successful of Union Autoparts Manufacturing Co.,Ltd. is from everyone support from board of director to our general staffs. All of this are our proud and one of the important part to make Union Autoparts Manufacturing Co.,Ltd. continuously to improve our performance.

IM : Image dimension

Universal testing

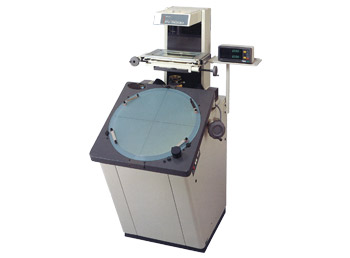

Profile Projector & Micro paker

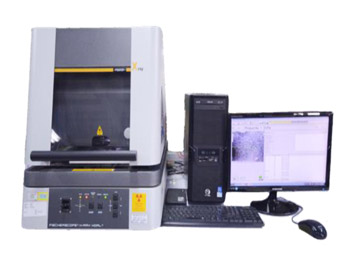

XRF : X-Ray Fluorescence

Corrosion resistance test

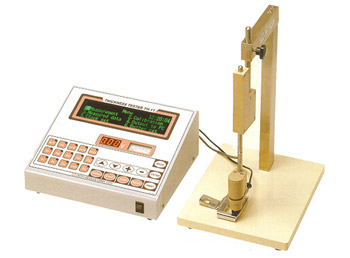

Thickness tester

Microscope

Microscope

ICP : Inductively coupled plasma

UV Visible Spectrophotometer

Total Organic Carbon

Couloscope CMS Step

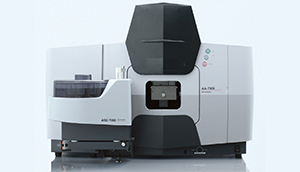

Atomic Absorption Spectrophotometers

Tritration

Environmental and Occupational health & Safety Achievements

Environmental Policy

Union Autoparts manufacturing Co.,Ltd. is a manufacturer of automotive parts such as wheels, wire spokes, etc., and provides electroplating services realized the importance of environmental quality and is committed to improving, preventing pollution, and preserving the environment including promoting energy conservation which is an important responsibility in conducting business with society. Therefore, establishing the environmental management system policy as follows,

- Committed to environmental management in accordance with the requirements of laws and other relevant regulations.

- Promote energy conservation. Everyone participates and the efficient use of natural resources to reduce carbon emissions. Promote the use of clean energy.

- Strengthen understanding and cultivate environmental awareness among employees at all levels and cooperate with surrounding communities in preserving the environment.

- Develop production processes and products to have the least impact on the environment. and maintain quality products Including the control of prohibited substances in products to meet customer requirements.

- Continuously support environmental development based on OKAYA Compliance.

ISO 14001 Qualification from Socotec Thailand Co., Ltd.

Safety Activities

- Inside and Outside Safety Campaigns such as Safety Patrol, Safety Talk, KYT, CCCF, Safety Dojo, JSA., etc.

Environmental Activities and Energy Saving

- Sort out the garbage for recycling instead of burning or landfilling.

- Use clean material.

- Water recycling to reuse.

- Save energy campaign and send report under energy policy.

- We use solar rooftop energy to reduce carbon emissions. Sustainable energy for the future.

CSR

- Scholarship Ceremony for company staff’s children.

- Social Donation.

- Education Donation.

Surveillance environmental impact

Environmental and Occupational health & Safety Achievements

- Clean and Green Technology Award.

- Certification of Achievement for the campaign of no drugs and working accidents along Poochaosamingprai Road.

- Green Industry Level 3 Factory Certification.

| Subject | Item | Detail | Institute / Customer | Year | Remark |

| Quality | 1 | Zero Defect Quality Control for 3 years in the row | Thai Honda Manufacturing Co.Ltd. | - | |

| 2 | Zero Defect Quality Control within 1 year | Thai Honda Manufacturing Co.Ltd. | 2003 | ||

| 3 | In honor of comparative best vender that pay attention and cooperation to achieve out standard production in the fields of quality production | Thai Suzuki Motor Manufacturing Co.Ltd. | 2007 | ||

| 4 | Quality target successful in 2008 | Thai Yamaha Motor Manufacturing Co.Ltd. | 2008 | ||

| 5 | Bronze Award : Outstand Autoparts Quality | Hino Motors Manufacturing (Thailand) co.,Ltd. | 2011 | First time | |

| 6 | Bronze Award : Outstand Autoparts Quality | Hino Motors Manufacturing (Thailand) co.,Ltd. | 2012 | Second time | |

| 7 | Gold Award : Outstand Autoparts Supplier | Hino Motors Manufacturing (Thailand) co.,Ltd. | 2012 | ||

| 8 | Excellent cooperation and Quality improvement award 2012 | Mitsubishi Electric Thai Autoparts Co.,Ltd. | 2012 | ||

| 9 | Award of Quality 213 | Mitsubishi Motors (Thailand) Co.,Ltd. | 2013 | ||

| 10 | Certificate of Excellent Quality and Delivery Performance 2013 | Bangkok Komatsu Co.,Ltd. | 2013 | ||

| Cost Reduction | 1 | Cost reduction award 2010 | Thai Yamaha Motor Manufacturing Co.Ltd. | 2010 | First time |

| 2 | Cost reduction award 2011 | Thai Yamaha Motor Manufacturing Co.Ltd. | 2011 | Second time | |

| 3 | Drive 55 Achievement award 2011 | Thai Yamaha Motor Manufacturing Co.Ltd. | 2011 | ||

| 4 | Best Supplier Award FY 2011 ( Good : C & D ) | Sunstar engineering (Thailand ) Co.,Ltd. | 2011 | ||

| 5 | Cost Co-Operation Activity 2011 | Yamasei Thai Co.,Ltd. | 2011 | ||

| 6 | Cost reduction, Co-operation Activity 2012 | Yamasei Thai Co.,Ltd. | 2012 | ||

| 7 | Cost Reduction Award | Hino Motors Manufacturing (Thailand) co.,Ltd. | 2012 | ||

| Environment | 1 | Clean & Green Technology Award 2011 | Department of industial | 2011 | |

| 2 | Environmental Good Governance Award | Department of Industrial | 2012 | ||

| 3 | Green Industry Award 2013 | Department of industial | 2013 | ||

| 4 | Level 3 Green Factory Certification | Department of Industrial | 2013 | ||

| Safety | 1 | The campaign no drugs and no working accident along Poochaosamingpria Road. | Minitry of labour | 2013 | |

| Performance | 1 | Smaller,Fewer,Lighter,Shorter,More Beautiful Activities 2011 : Gold Award | Okaya & Co.,Ltd. | 2011 | First time |

| 2 | Smaller,Fewer,Lighter,Shorter,More Beautiful Activities 2012 : Gold Award | Okaya & Co.,Ltd. | 2012 |

Ready to serve

TEL (02) 183-3872

Copyright © 2016 Union Autoparts Manufacturing Co., Ltd. All rights reserved.

Designed by Giant Point

Comments are closed.